鍛冶職人 赤畠大徳 黒打三徳包丁 165mm

赤畠大徳

Blacksmith Daitoku Akahata | Black-forged Santoku knife 165mm

在庫数: 在庫なし[出荷予定日]

Ships in approximately 2-3 weeks (on backorder) *We will contact you if there is a delay.

Santoku knives made by blacksmiths

This Santoku knife is made by Akahata Daitoku, the fifth generation blacksmith of "Kajiyasu Daitoku," whose workshop is located in Matsusaka City, Mie Prefecture. Unlike mass-produced knives available on the market, the Santoku knives made by blacksmith Akahata are fire-forged and hammered to create a black-finished Santoku knife.We also use Akahata knives at home.

Thump, thump...

A truly sharp knife has a blade that will naturally sharpen without the need for force. Recommended for those who want to use it for a long time.

[Top: Kurouchi Santoku knife, bottom: Kurouchi paring knife]

[Top: Kurouchi Santoku knife, bottom: Kurouchi paring knife]As the first book

Santoku knives, which can be used for any type of food, including meat, fish, and vegetables, are also called cultural knives or all-purpose knives, and are recommended as the first household knife. The sharpened edge of a forged knife brings out the flavor of the food without damaging it, making your cooking even more delicious. Also, since it is double-edged, it can be used by either left-handed or right-handed people.

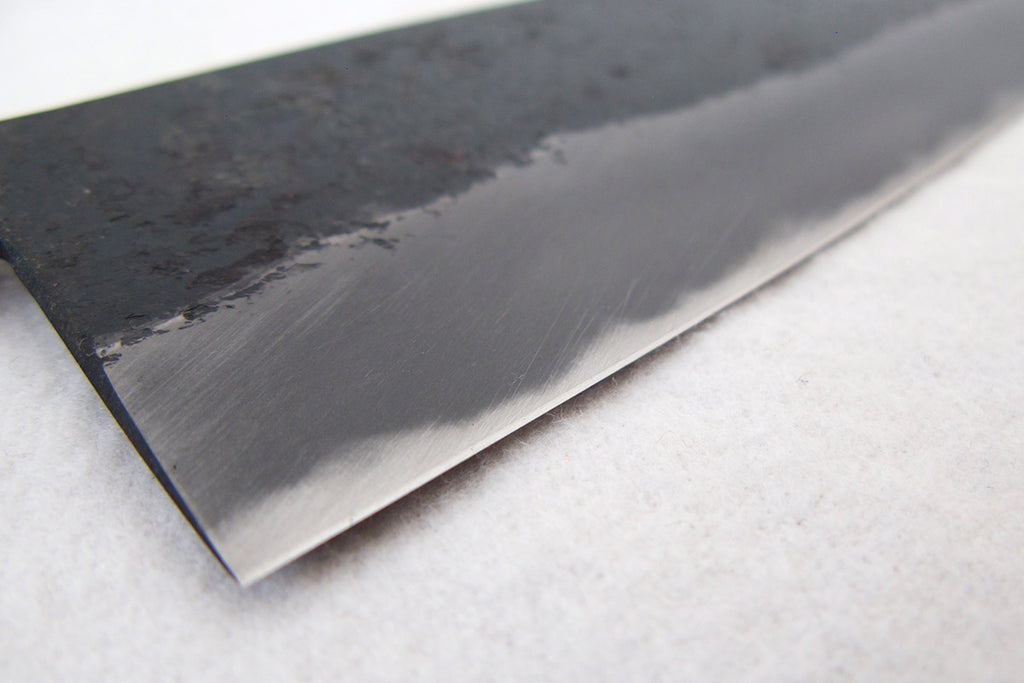

Black finish knife

A Kurouchi knife that intentionally leaves the surface blackened by hardening. The rugged look with visible marks of hammering is very appealing. It is also said to be less prone to rust than knives that are polished all over. This knife goes well with the wooden handle and has an excellent design.

Strong and sharp cutting edge

A strong knife is created by hammering, forging, hardening, and tempering. The strength of the material changes depending on how it is heated and how red it is, so the skill and experience of the craftsman is important. In addition, to ensure a sharp cutting edge, Akahata-san personally sharpens the knife by hand.

Easy to hold wooden handle

The handle is made of solid black walnut. The uneven surface created by the scraping marks makes it easy to grip and use. This carving is done thoroughly by Akahata, without relying on machines, using a knife in three separate steps. After the core is inserted into the wood of the blade and handle, they are fixed in place with brass.

Inscription

Finally, an inscription is engraved on the piece to prove that it was made by Akahata, and the piece is complete.

Knives you'll want to have in your home

Akahata's knife series. We have a selection of knives that you'll want to have in your home for everyday use. [From the left: Black-finished bread knife 210mm, Black-finished bread knife 120mm, Black-finished santoku knife 165mm, Black-finished paring knife 120mm]

[From the left: Black-finished bread knife 210mm, Black-finished bread knife 120mm, Black-finished santoku knife 165mm, Black-finished paring knife 120mm]Delivered in a nice box

From now on, it will be delivered in a box. According to Akahata, the design was inspired by the image of a sword being drawn from its sheath. You can enjoy watching the knife take shape, thanks to the unique ideas of a blacksmith. It is also recommended as a gift.

Easy maintenance

Although it is often thought that it is difficult to maintain a forged knife, it is actually very easy to maintain. Just like a normal knife, rinse it thoroughly after use to remove any dirt, wipe it dry thoroughly and store it away. Due to the characteristics of iron, if it rusts, remove the rust using a cleanser or eraser-type rust remover.For wooden handles, apply walnut oil or perilla oil to a paper towel once every six months where you feel the oil has worn off. After applying, wipe off any excess oil and let dry in a well-ventilated, shady area. *When applying oil, be sure to wet the kitchen paper with water before disposing of it.

Resharpening

To ensure that you can use the knife for a long time, Mr. Akahata will provide sharpening and maintenance services. The customer will be responsible for the round-trip shipping fee and maintenance fee. If you would like to do so, please contact us. Kajiyasu was founded in April 1894. The first to third generations of the company were engaged in the manufacture of agricultural and forestry tools. The fourth generation did not engage in blacksmithing, but started an ironworks and construction business. After the third generation (grandfather) passed away, the blacksmithing business was suspended for about 20 years, but the fifth generation, Akahata Daitoku, wanted to revive the blacksmithing business, and studied under Yamaguchi Teichiro, the head of Kyoto's knife blacksmith "Yoshisada", and opened Kajiyasu Daitoku in April 2008, where it remains to this day.

Kajiyasu was founded in April 1894. The first to third generations of the company were engaged in the manufacture of agricultural and forestry tools. The fourth generation did not engage in blacksmithing, but started an ironworks and construction business. After the third generation (grandfather) passed away, the blacksmithing business was suspended for about 20 years, but the fifth generation, Akahata Daitoku, wanted to revive the blacksmithing business, and studied under Yamaguchi Teichiro, the head of Kyoto's knife blacksmith "Yoshisada", and opened Kajiyasu Daitoku in April 2008, where it remains to this day.Click here for a list of works by Daitoku Akahata

This Santoku knife is made by Akahata Daitoku, the fifth generation blacksmith of "Kajiyasu Daitoku". Unlike mass-produced knives available on the market, this Santoku knife is made by fire forging and forging the steel, giving it a black finish.

[Product name] Kurouchi Santoku knife 165mm

[Size (approx.)] Total length 294mm, blade 178mm, blade length 165mm

Weight (approx.): 132g

[Material] Blade: Steel, iron, handle: Black walnut (solid), brass

[Paint] Pattern: Walnut oil

[Notes] Double-edged type that can be used by both left-handed and right-handed people

● Precautions for use

・When using for the first time, wash with dishwashing detergent or similar before use.

・After use, wash off dirt with dishwashing detergent or similar and wipe off any water.

Dishwasher/dryer ×

●Please be sure to check before purchasing.

・As all items are handmade, there may be individual differences in size, weight, color, unevenness, shape, etc.

-Even if the wood used for the pattern is the same, each piece has its own unique appearance, so the grain and coloring will vary.

Please enjoy this as a unique feature of this product, which is unlike any other in the world.

Please be aware of the above before making your purchase.