石宏製作所 裁ち鋏 東京スカイツリーのテープカットに使用

石宏製作所

Ishihiro Manufacturing Co., Ltd. | Cutting scissors used for the ribbon cutting ceremony at Tokyo Skytree

在庫数: 2[出荷予定日]

Orders placed before 5pm will be shipped within 2 business days

Ishihiro Seisakusho has been making medical scissors for two generations since 1970.

We have a workshop in Sumida, Tokyo, where Edo traditions and culture live on.

Each pair is still made by hand by second-generation scissors craftsman, Akio Ishida.

Ishihiro Seisakusho has been making medical scissors for two generations since 1970.

We have a workshop in Sumida, Tokyo, where Edo traditions and culture live on.

Each pair is still made by hand by second-generation scissors craftsman, Akio Ishida.The series of household items made for general household use, including "disassemblable scissors" and "dressing scissors," This series began with Ishida's desire to "hear what our customers have to say" and "know their reactions."

In 2011, it was certified as "Sumida Modern" as a regional brand product representing Sumida. In 2012, Ishihiro Seisakusho's cutting scissors were used for the ribbon cutting ceremony at Tokyo Skytree.

Please take a look at the video first. I think you will be able to see the charm of our products, which are made with love.

Scissors made by a scissors craftsman

Ishihiro Seisakusho's scissors are renowned for their quality, having been used for the ribbon-cutting ceremony of the Tokyo Skytree in 2012. They also weigh a reasonable 157g, making them extremely easy to use, with their sharpness and weight allowing for smooth, supple cutting.

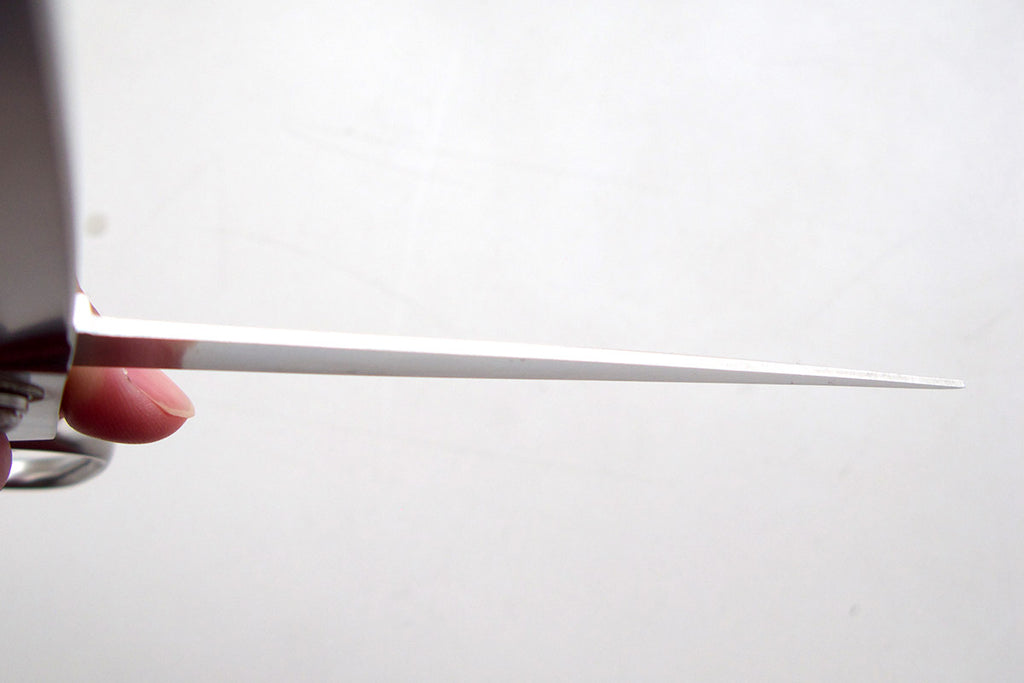

The twist is the key to sharpness

"It can cut even without a blade," says Ishida, "and the important thing is the bite." The scissors made by Ishida have an evenly cut inner blade, which you can feel by touching it, and it forms a smooth arc. He then adds a "twist" which is the key to sharpness. This allows the cutting surfaces to intersect at a single point, allowing the scissors to cut with less force. [Only the blades touch each other]

[Only the blades touch each other]  [When closed, only the crimped part is connected]

[When closed, only the crimped part is connected]This process of interlocking is the most important, and requires the skill and experience of a craftsman, something that machines can never replicate. Ishida's scissors make use of the know-how he has cultivated in the manufacture of medical scissors, and are characterized by their smooth movement and the feeling that the blades stick together when cutting.

[The back edge of the blade becomes less visible as it approaches the tip. This is because it has an inward twist.]

[The back edge of the blade becomes less visible as it approaches the tip. This is because it has an inward twist.]Making strong scissors

To create strong scissors that are hard and resilient, we use a type of stainless steel called "SUS420J2," which can be hardened. Hardening is done at 1030 degrees for two hours, and then tempering is done at 180 degrees to create a strong pair of scissors. Stainless steel is rust-resistant, and its hardness and resilience make it ideal for cutting fabric.

We accept name engraving

We can engrave your name in the area shown in the photo. (Name engraving fee: 1,000 yen extra) If you wish, please enter the name you would like engraved in the comments section when placing your order. (Only alphanumeric characters will be engraved)*If you would like your name engraved, delivery will take approximately 2 to 3 months from the time of your order.

Also great as a gift

It comes in a simple and luxurious package. This product also makes a great gift.

Resharpening

To ensure that you can use your knife for a long time, Mr. Ishida will provide resharpening and maintenance. The customer is responsible for the round-trip shipping and maintenance fees. If you would like to have this service provided, please contact us. [Ishihiro Seisakusho scissors series. From left: dressmaking scissors, scissors given by a craftsman to a loved one, thread scissors, eyebrow scissors, and 14-inch round scissors (for small children)]

[Ishihiro Seisakusho scissors series. From left: dressmaking scissors, scissors given by a craftsman to a loved one, thread scissors, eyebrow scissors, and 14-inch round scissors (for small children)]  Founded in 1970, the company has been manufacturing medical scissors since its founding. While making medical scissors, second-generation owner Akio Ishida began using his skills to make scissors for general household use, driven by a desire to "hear what customers have to say" and "know their reactions." In 2011, 2013, and 2016, the company won the Sumida Modern Award. In 2012, their "cutting scissors" were used in the ribbon-cutting ceremony at the Tokyo Skytree, and they have received high praise from all quarters.

Founded in 1970, the company has been manufacturing medical scissors since its founding. While making medical scissors, second-generation owner Akio Ishida began using his skills to make scissors for general household use, driven by a desire to "hear what customers have to say" and "know their reactions." In 2011, 2013, and 2016, the company won the Sumida Modern Award. In 2012, their "cutting scissors" were used in the ribbon-cutting ceremony at the Tokyo Skytree, and they have received high praise from all quarters.Ishihiro Seisakusho's cutting scissors are renowned for their quality, having been used for the ribbon-cutting ceremony of the Tokyo Skytree in 2012. The sharpness and weight of the scissors make them very easy to use, allowing for smooth, flexible cutting.

[Product name] Cutting scissors

[Package size (approx.)] W252 x D78 x H21mm

Product size (approx.): W240 x D65 x H18mm

[Weight (approx.)] 157g

[Material] Stainless steel (SUS420J2)

[Note] Certified as "Sumida Modern" in 2011. Scissors used for the ribbon cutting ceremony at Tokyo Skytree.

[Country of Origin] Made in Japan (Sumida-ku, Tokyo)

● Precautions for use

-If you wash it with water, be sure to wipe it immediately after washing and dry it thoroughly.

-As this is a bladed tool, please handle with care to avoid injury.

- When not in use, store out of reach of children.